Liftable and self-steerable axles: front or rear of axle groups?

Liftable and self-steerable trailer axles are recognised for improving vehicle performance in terms of fuel economy and low-speed manoeuvrability as well as reducing tyre scrub. However, the choice of where to fit the liftable or self-steerable axles within an axle group is not a trivial question!

There are multiple factors contributing to pros and cons of each. In this article, we will provide the results of a case study which shows how and to what extent positioning of the liftable/self-steerable axles could affect a combination’s performance, focusing on low-speed Performance Based Standard (PBS) scheme, namely Low-Speed Swept Path (LSSP).

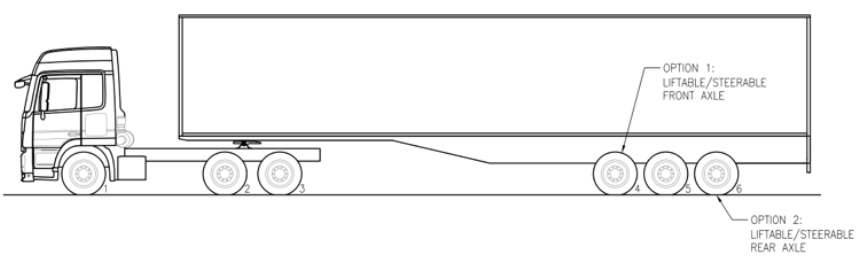

The example combination under investigation is a 20m 6×4 prime mover and tri‑axle semi‑trailer which has been subjected to low-speed standards check as per PBS standards. To have a more conclusive comparison, we will look at liftables and steerables, separately.

Figure 1 – A semi-trailer with front axle being lifted (courtesy of www.stas.be)

Figure 2 – Possible configurations assessed

What do the Australian Design Rules (ADRs) say about liftable and self-steerable axles?

The ADR 43/04 refer to liftable axles as “retractable axles” and defines a set of “transition masses” for the axle groups below which the liftable axles are allowed to be lifted. When an axle is lifted or is steerable, that axle is not counted for determining the centre of the axle group, otherwise known as rear overhang line, for the purpose of vehicle lengths determinations.

Considering the above is important because wheelbase, S-dimension, and rear overhang are measured with reference to the location of rear overhang line as specified in the Heavy Vehicle National Law (HVNL). For example, if a self-steerable axle group is fitted to the rear of an axle group, the S-dimension is decreased, and the rear overhang is increased compared to a non-steerable axle group. On the other hand, if a self-steerable axle is fitted to the front of an axle group, the S-dimension is increased while the rear overhang gets shorter.

This particularly gets important in determining if the combination complies with ADRs or if any exemptions should be sought. Furthermore, if the combination suffers from a large tail swing as set out in PBS, the rear overhang may need to be reduced.

Now, let us look at things from a performance perspective.

Liftable axle positioning

Lifted axles are allowed when the combination is operating unladen or when the axle group load is below the “transition mass” specified in ADR 43/04 (for quad axle groups, view here). Lifting of the axles reduces tyre-road friction and therefore results in better fuel economy as well as minimising tyre wear. Up to this point, it doesn’t seem to matter whether the front axle is lifted or the rear axle. However, let’s look at it from a low-speed turning performance perspective.

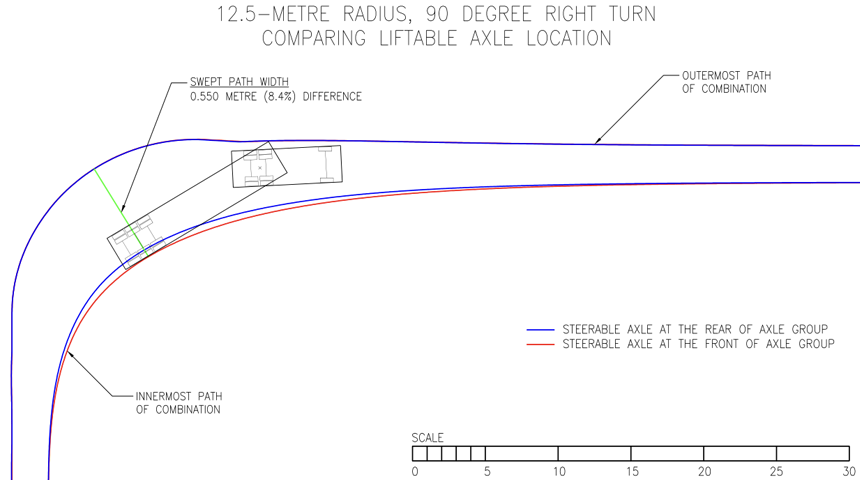

Figure 2 shows the LSSP envelope of the two cases, namely having the front axle lifted versus having the rear axle lifted. The results suggest that rear-fitted liftable axle reduced LSSP width by 0.550 metres which equates to 8.4% improvement as far as this PBS standard is concerned. However, it must be noted that the PBS assessment of combinations normally involves both laden and unladen simulations. Therefore, the addition of a liftable axle at front of axle group does not necessarily help with meeting better PBS Levels, unless the vehicle is only restricted to unladen (or below transition mass) operation.

Figure 3 – Comparison between positioning the liftable axle at front vs rear of trailer axle group

Self-steerable axle positioning

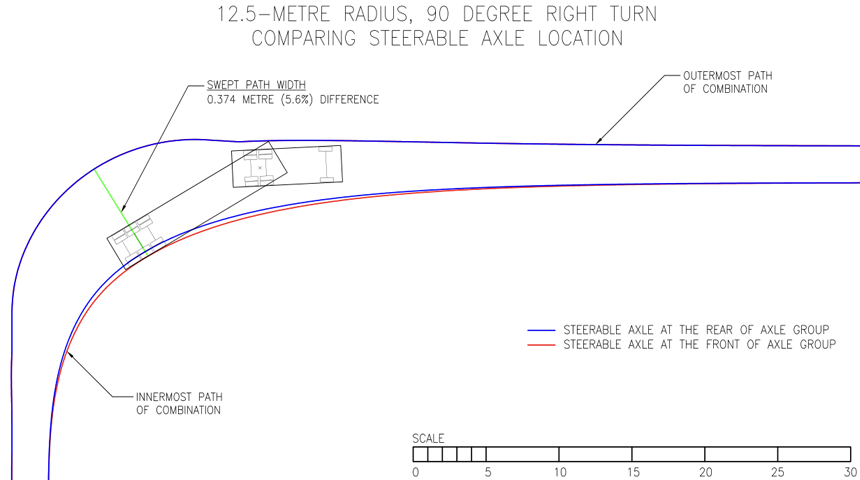

Now, let’s have a look at the same comparison but for self-steerable axle positioning. As indicated in Figure 3, the vehicle with a rear-fitted self-steerable axle tracks inwards by a smaller width while turning compared to front-fitted self-steerable. The improvement in swept-path width is about 0.374 metres or 5.6%.

Figure 4 – Comparison between positioning the self-steerable axle at front vs rear of trailer axle group.

Conclusion

The comparison presented above has been applied to a certain combination, but the trend of results is expandable to any vehicle combination with liftable or self-steerable trailer axles. In terms of LSSP performance of combinations with liftable or self-steerable axles, it is more beneficial to fit the self-steerable or liftable axle at the rear of the axle group rather than front if you are seeking to improve LSSP performance. The difference could be a critical factor for meeting the requirements for the PBS Level of interest. Therefore, for the combinations that perform marginally close to their intended LSSP limits, it is advisable to position the self-steerable or liftable axle at the rear of axle group, if feasible, from the PBS standards’ perspective.

That being said, due to the generally contradictory nature of vehicle performance at low and high speeds, the high-speed performance of combinations normally does not benefit from either liftable or self-steerable axles. Therefore, if such a situation arises that the high-speed performance is compromised to an extent that combination fails to meet the intended PBS Level, an additional operating condition requiring the self-steerable axles to be locked at high-speeds or liftable axles not lifted at high-speeds will be applied.

An exemption to the above conclusion is when the tail-swing standard is critical as well. In that case, having the liftable or self-steerable axle at the front might help by moving the rear overhang line further back at the expense of increasing LSSP.

Contact Advantia if you would like to investigate PBS opportunities for your business.

Get more like this in your inbox

Subscribe to our Newsletter and never miss a post.